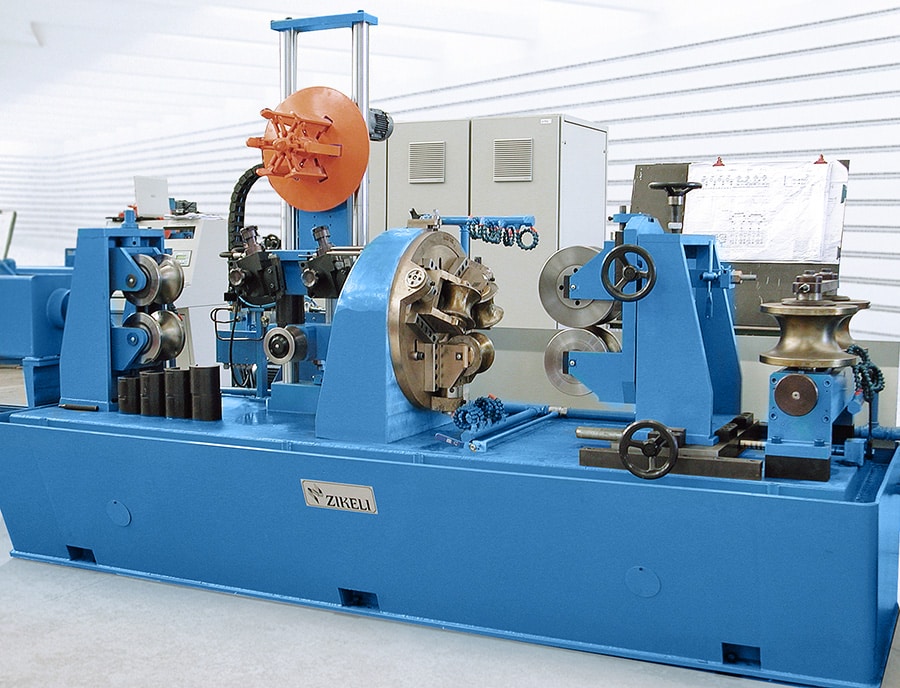

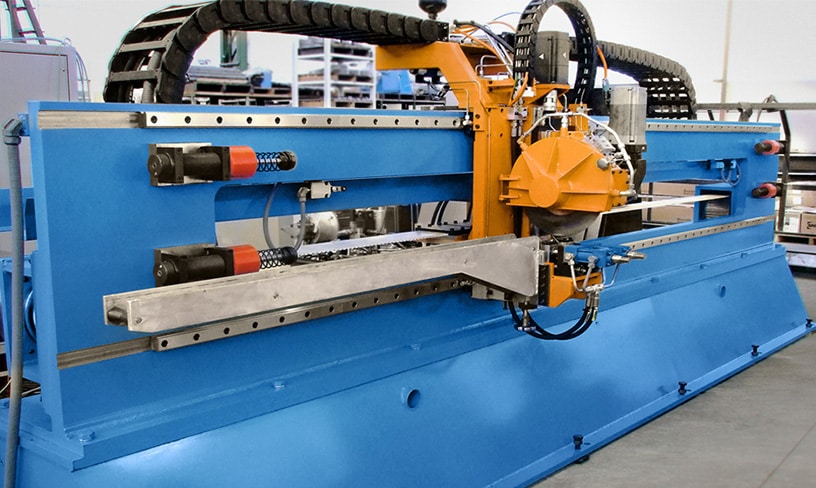

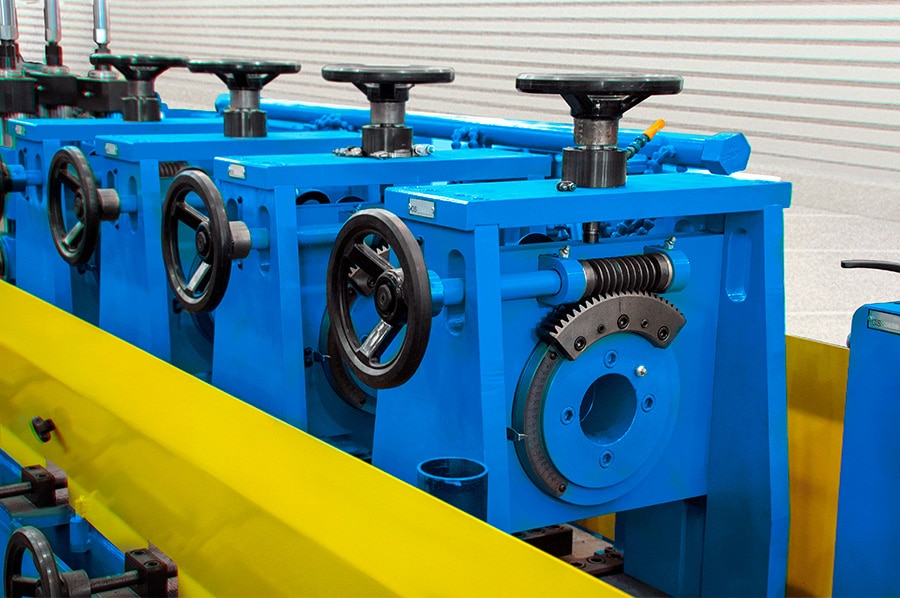

Tube Formers:

Modelo ITL

At the beginning of the 1950s, through the boldness and genius of its founder, Eng. Kurt Otto Zikeli, one of the first tube formers in Brazil was built.

With oxy-acetylene welding, the only one available at the time, a speed of 4 m/min was achieved. A total success!

Through continuous research and development work, the design of today's forming machines offers customers an excellent return on investment, with guaranteed high working speeds, quality formed products and total machine reliability and technical assistance.

With more than 100 tube formers in operation, Zikeli is the market leader and the largest and best manufacturer of these machines in Latin America.

| Technical specifications | ITL 50 x 2 | ITL 75 x 4 | ITL 100 x 3 | ITL 130 x 4 | ITL 130 x 6 |

| Diâmetro ext. dos tubos (mm) | ø½”-ø2″ | ø¾”-ø3″ | ø1″-ø4″ | ø1/4″-ø5″ | ø2”-ø5” |

| Espessura SAE 1010(mm) | 0,60 a 2,25 | 0,75 a 3,75 | 0,90 a 3,00 | 0,90 a 3,75 | 2,00 a 6,30 |

| Velocidade de trabalho (m/min.) | 90 a 160 | 80 a 120 | 60 a 100 | 50 a 80 | 25 a 60 |

| Gerador de alta frequência (kW) | 200 | 250 | 250 | 300 | 350 |